Suction of dissolved fat and oils.

This application is rather singular, pumping dissolved fat and oils. A food company specialized in bakery on industrial scale, has the need to collect the fluids arising from operations of cooking of foods made of meat. The fluid that is generated is largely composed of animal dissolved fat and oils, solid formations deriving from the cooking process. The fluid is collected in trays rather wide but of a few centimeters in height. The amount of fluid that collects for each process is relatively low but still in the order of 1500-2000 liters for “baked”.

This application is rather singular, pumping dissolved fat and oils. A food company specialized in bakery on industrial scale, has the need to collect the fluids arising from operations of cooking of foods made of meat. The fluid that is generated is largely composed of animal dissolved fat and oils, solid formations deriving from the cooking process. The fluid is collected in trays rather wide but of a few centimeters in height. The amount of fluid that collects for each process is relatively low but still in the order of 1500-2000 liters for “baked”.

The difficulty of process consists in the aspiration of fluid mass with relative solid suspension, whereas having to do that at an optimal temperature pointed to maintain fluidity status. The operation must be carried out quickly and occurs by inserting the pump intake pipe equipped with a suitable terminal designed to drain the maximum possible in various points of collection tank. The fluid is then accumulated in tanks and repositioned for energy purposes. The company attended to perform the recovery and transfer operation manually using containers self-purpose built, but obviously in a very long time.

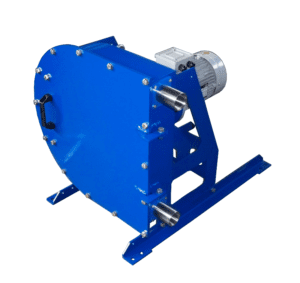

In a first time was used a peristaltic pump HCP 25 to perform the operation of the suction of the oil and grease dissolved. Verified the validity of the solution applied, the company has subsequently purchased a new peristaltic pump of greater dimension in such a way to be able to solve the problem of the recovery of substances arising from seasonal peaks of production, a peristaltic pump HCP 40 is added to the previous HCP 25 already in use.

The company now has a couple of machines perfectly sized for the productive needs, ordinary and extraordinary, and resolved quickly and clean the problem of oils and fats dissolved suction, with heterogeneous suspensions resulting from rotisserie processes.

More information on Hose Carrier HCP 40

I’m interested but without obligation, keep me informed